New Research Reveals Operational Downtime Poses a Significant Risk for Businesses That Neglect Their Drainage Systems

Thousands of businesses are prioritising office refurbishments over drainage maintenance, leaving them at risk of disruption from operational downtime – something many say is their biggest challenge today.

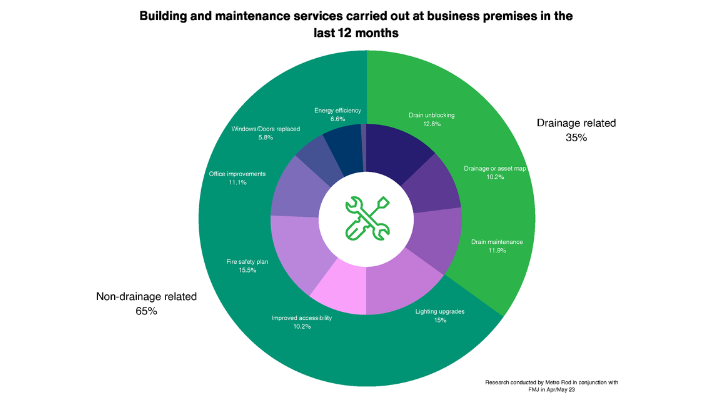

A recent survey conducted by Metro Rod, in partnership with FMJ, shed light on the challenges faced by businesses with operational downtime emerging as one of the most significant challenges for respondents, ranking just behind material shortages. Staff skill shortages, energy prices, and rising costs followed closely behind. When asked about the activities they’ve conducted in their business in the last 12 months, a significant portion reported focusing on non-drainage-related endeavours such as lighting upgrades, office improvements, accessibility improvements and window and door replacements. Surprisingly, less than a quarter have invested in a drainage or asset map – despite nearly one-third saying they’ve experienced drain blockages in the past year and a similar percentage incurring drain maintenance expenses.

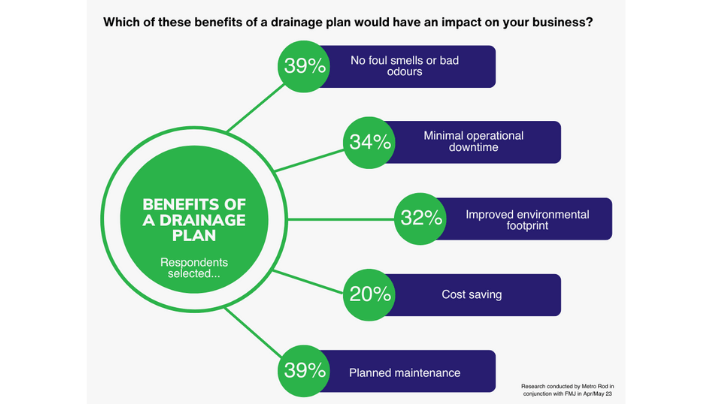

The survey also highlighted that respondents recognised the benefits of having a drainage plan in place. They identified planned maintenance, no foul smells or odours, minimal operational downtime, and an improved environmental footprint as the advantages. Despite this, only 38% had a pre-planned maintenance (PPM) plan, leaving a significant portion of businesses unaware of the condition of their underground drainage system.

Furthermore, many revealed they’re only engaging with drainage maintenance companies in an emergency or when they know something isn’t working properly – the moment at which they could be forced to close their doors.

The Benefits of Pre-Planned Maintenance

Operational downtime can lead to a loss of income, poor reviews and damage to a brand’s reputation. So why, when drainage can have such an impact on business do so many not have a proactive plan in place to ensure their drains flow freely?

Working in partnership with facilities management providers, we’re encouraging businesses across the UK to invest in pre-planned maintenance, so businesses of all kinds can keep their premises fully operational.

PPM to Avoid Operational Downtime

PPM is a service plan which can be put in place for routine drainage and pump maintenance. It can be scheduled at regular intervals to suit your and your customers’ schedule, for example during quiet periods and out of hours. PPM is used to prevent scale or grease build-up in pipework and the problems that can lead to foul smells, overflowing waste and emergency call-outs. Ultimately they are in place to help drive cost savings and improve efficiencies for your business.

The Typical Works Covered by a PPM Schedule are:

- Drain and pipework cleaning

- High-pressure water jetting

- Gully clearance

- Gutter clearance

- Urinal descaling

- Grease trap emptying and cleaning

- Interceptor maintenance

- Shower trap and hand basin trap cleaning

- Service of sewage and freshwater pumps

- CCTV drain surveys to identify problems

We recommend a visit from a drainage engineer every six to twelve months depending on the site and how frequently each facility is used.

Pollution Prevention

Another benefit of pre-planned maintenance is pollution prevention, and with 72% of respondents saying pollution prevention is a priority for their business, it demonstrates the urgency and importance of setting a plan which is tailored to your business.

Drain maintenance goes a long way towards creating a properly functioning drainage system and reducing the risk of contaminants entering the watercourse. For example, drain cleaning removes debris, sediment and other materials which accumulate, which when left to build up could lead to sewage overflowing. CCTV drain surveys help identify cracks, leaks and any damage; this is the first step to reducing the cost of large repairs by acting early before drains deteriorate further, but importantly for the environment surveys identify any misconnections or leakage of contaminated waste.

A well-executed drain maintenance plan can help ensure your business has the proper disposal of waste in place. Routine collecting of grease from grease traps will ensure their continued correct operation, reducing problems of blockages in foul water sewers. Routine maintenance of petrol interceptors will ensure similar protection of our surface water sewers and watercourses. Maintenance practices such as these will help ensure legislative compliance in addition to safeguarding our environment to the benefit of all.

When businesses face such a wealth of problems, the risk of downtime because of drainage shouldn’t be one of them. By proactively investing in drainage plans and adhering to proper waste disposal practices, businesses can minimise operational downtime, protect their bottom line and prevention pollution.

For more information on Pre-Planned Maintenance or how to reduce the impact of operational downtime through drainage solutions, contact your local Metro Rod or call us on 0800 66 88 00.

Talk to your local Metro Rod specialist

We are always happy to arrange a free site assessment and no obligation quotations for any work you might need. Alternatively, you can call our emergency hotline number on 0800 66 88 00

Get in touch Drainage Services